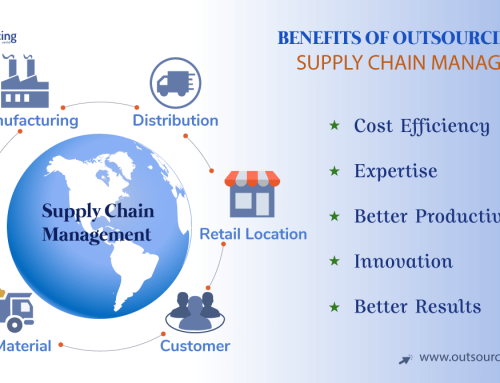

A business establishes a network of supply chain and its services (or “links” in the chain”) to convey the product from raw material suppliers to businesses that interact with customers directly.

To handle the flow of a good or service – starting from the raw components all the way to delivering the final product to the consumer.

In answer to the above asked question, How To Change The Challenges Into Solutions?: Supply Chain Sourcing.

Companies need a well-organized supply chain services if they want to stay competitive. It will provide high-quality goods and services while lowering costs and reducing negative consequences.

It will also have a big impact on how long it takes you. Solid sourcing will increase the efficiency of your process. The cornerstone of sourcing is the connection between the buyer and the supplier.

Have You Heard? 6% of companies assert that they have total visibility over their supply chain services. Just 69% of companies have total visibility.

What Can Be The Most Common Obstacles?

- There can be an absence of transparency. Stakeholders can view the current state of the supply chain services sourcing thanks to transparency.

- A poor manufacturing cycle produces waste. Businesses that incorrectly estimate supply, demand, or capabilities risk having an overstocked inventory.

- Dissatisfied clients and business associates. The ultimate goal of sourcing in supply chain services management is to meet customer expectations.

- Customer demands are increasing. New businesses and technologies boost customer expectations, which can be challenging to manage and impossible to satisfy if handled incorrectly.

- Resilience in the face of disturbances in the supply chain. The interruptions might be caused by external factors, thus it’s important to plan for the improbable and be able to change course if necessary.

- Products that have been delayed or lost. The entire supply chain services sourcing process is slowed down by items that go missing at any step, which might have a bad effect on customers.

3 Important Facts To Know About Supply Chain Services Sourcing

- A supply chain services source management’s duties include cost control, cost reduction, and preventing supply shortages

- Supply chain sourcing management, which includes all processes that turn resources into product items, is the central management of the flow of products and services.

- Supply chain services management shields companies from costly recalls and legal action as well as the media.

The Best Techniques For Dealing With These Issues

- Apply lean sourcing techniques to supply chain sourcing and logistics management. Lean increases adaptability while decreasing wasteful inventories.

- Boost the pace of inventory turnover. Companies must ensure that supply does not outpace demand and that, via lean management, they can profit from dispersed, fast shifting demand.

- Businesses must interact with other companies in their supply chain services in order to improve the overall strategic sourcing process in supply chain management, not simply a single company’s process.

- Cycles ought to be cut shorter. Businesses should strive to keep them as small as possible in order to satisfy customer expectations.

- Make advantage of technology for supply sourcing. Technology may help managers connect their supply chains and improve communication.

- Establish relevant measurements. By employing clear KPIs, managers can assess the chain’s efficiency.

What Modifications To The Services May Boost Sales?

The supply chain services are the “face” of the company that customers and consumers see the most. A company’s corporate reputation and long-term viability are better protected the better and more effectively its SC management is implemented.

- Connected

Gaining access to conventional data sets made available by standard ERP and B2B integration solutions as well as unstructured data from social media and structured data from the Internet of Things (IoT). - Collaborative

As multi-enterprise cooperation and engagement become more important, cloud-based commerce networks are being used to improve supplier collaboration. - Cyber-Aware

The chain should be worried about hardening its systems and securing them against hacking and online invasions. - Mentally Capable

By compiling, coordinating, and leading choices and activities across the chain, the AI platform transforms into the control tower of the contemporary chain. The majority of the chain is self-learning and automated. - Comprehensive

Real-time data needs scale analytics capabilities. The insights will come quickly and thoroughly. The chain of the future cannot tolerate latency.