Supply Chain Sourcing: Shifting Challenges And Opportunities

The web of individuals, companies, assets, operations, and systems involved in the manufacture and distribution of its products is referred to as a supply chain. Everything from the distribution of raw materials from a supplier to the producer to the final delivery to the end user is included in a supply chain sourcing.

The distribution channel is the part of the supply sourcing responsible for transferring the final product from the producer to the customer.

Did You Know? Only 6% of businesses claim to have complete visibility into their supply chain. Only 69% of businesses have complete visibility.

PRINCIPLE POINTS:

- Supply chain sourcing management is the centralized administration of the flow of goods and services, and it encompasses all operations that transform resources into product items.

- Supply chain management keeps businesses out of the news and out of costly recalls and lawsuits.

- Controlling and decreasing costs, as well as avoiding supply shortages, are the responsibilities of a supply chain sourcing management.

Companies In Bangladesh Are Still Not Aware Of The Necessity Of Supply Sourcing

Strategic sourcing in supply chain management is not just beneficial, it is a crucial part that every company should have included in their operations. Let’s see in Bangladesh’s scenario how many companies utilize supply chain sourcing.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Most Common Challenges Faced While Supply Sourcing

Modern supply chain sourcing is complicated and faces a number of issues. These are the following:

- There could be a lack of transparency. Transparency allows stakeholders to see where the supply chain sourcing is at any give time.

- Inadequate production cycle results in waste. Businesses who misjudge supply, demand, or capabilities may find themselves with an oversupplied stock.

- Customers and business partners who are dissatisfied. Customer expectations are the ultimate purpose of sourcing in supply chain management.

- Goods that have been lost or delayed. Items that go AWOL at any point in the supply chain slow down the entire supply chain sourcing process and might have a negative impact on customers.

- Customer expectations are rising. Customer expectations are raise by new technology and enterprises, which can be hard to manage and impossible to achieve if not manage correctly.

- Resilience in the face of supply chain disruptions. External causes might cause supply sourcing disruptions, so it’s best to plan for the unpredictable and be able to transition if necessary.

Now Let’s Check Out The Best Practices For Overcoming These Challenges

- Make use of lean sourcing in supply chain sourcing management and logistics solutions. Lean improves flexibility while reducing inventory waste.

- Increase the inventory turnover rate. Companies must guarantee that supply does not exceed demand and that they are able to capitalise on scattered, rapidly changing demand with lean management.

- To optimize the entire strategic sourcing in supply chain management, not just a single company’s process, firms must engage with other companies in their supply chain.

- Cycles should be short. To meet client expectations, businesses should try to keep them as minimal as feasible.

- Take use of supply sourcing technology. Managers can use technology to better connect their supply chains and interact.

- Put in place a meaningful metrics. Managers can properly measure the chain’s efficiency using well-defined KPIs.

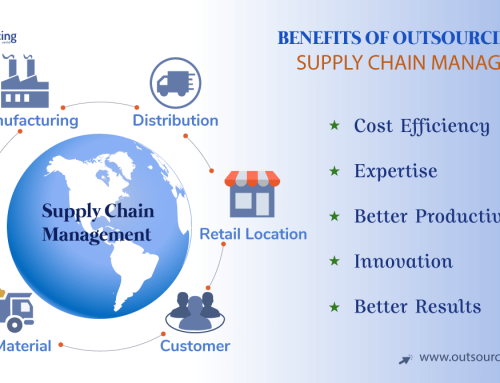

Advantages of Supply Chain Management

Effective supply chain management (SCM) brings numerous advantages to businesses, including:

1. Cost Efficiency: SCM helps in identifying and eliminating inefficiencies, leading to cost savings. This could be through optimizing inventory levels to reduce holding costs, improving delivery and as well as logistics to save on transportation costs, or streamlining processes to minimize waste.

2. Increased Productivity: By streamlining operations and improving coordination among different parts of the supply chain, SCM can significantly enhance productivity. This could translate into faster production times, quicker order fulfillment, and improved customer service.

3. Enhance Customer Satisfaction: Effective SCM ensures that products are delivered to the right place at the right time, enhancing customer satisfaction. It can also improve the ability to respond to changes in customer demand, enabling better service.

4. Competitive Advantage: An optimized supply chain can provide a significant competitive edge. It can enable faster delivery times, better quality control, lower costs, and also higher customer satisfaction, all of which can differentiate a company from its competitors.

5. Risk Mitigation: SCM includes risk management strategies to identify potential disruptions (like supplier failures, delivery delays, quality issues, or natural disasters) and create contingency plans. This can enhance the resilience of a business and also reduce the impact of supply chain disruptions.

Driving Bangladeshi Companies With Our Successful Supply Sourcing Services

We can assist you in achieving a variety of business goals. Controlling manufacturing processes, for example, can help you enhance product quality while lowering the risk of refunds and lawsuits. We can also help you develop a strong customer brand. Controlling shipping methods, on the other hand, will improve customer experience by preventing possible shortfalls or periods of inventory overstock. Visit our website today to learn more about our strategic sourcing in supply chain management!